02.03.2015 Istanbul

Application of Magnetostrictive Probe and Mounting Kit for Lpg Tank

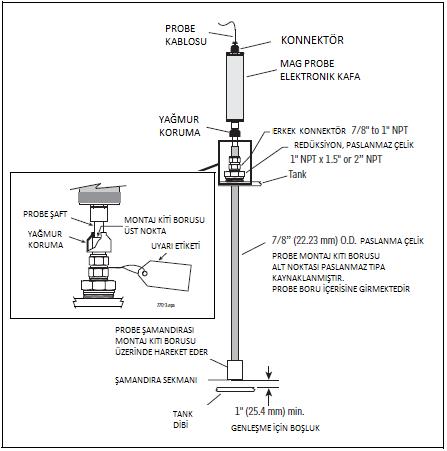

Magnetostrictive probe technology with high measurement accuracy can also be used for LPG and other approved products stored in pressurized tanks. In such tanks, level probes are specially designed against possible pressure losses.It is used in conjunction with the K Assembly Kit with improved high insulation standards.

Installation kits are stored in the tankIt is produced from material suitable for the type of rune, it remains fixed in the tank after installation and the float that will affect the probe moves parallel to the liquid level on this scarce. Just like a sheath, the level probe is inserted into this kit to provide liquid spel

Its possession is measured. Intervention in possible probe failures can be easily done without any pressure loss thanks to this scarcity.

METHOD OF APPLICATION AND EXPLANATIONS

MATERIALS USED AND DESCRIPTIONS

METAL ADAPTER MANUFACTURED FOR 35 MM TANK INLET

In LPG tanks, it is possible to install magnetostrictive LPG probe by disassembling the Rochester level gauge. The Veeder Root range includes a 35 mm diameter tank inlet float on which the Rochester level gauge is mounted. For the assemblies to be made from this point, the metal adapter shown in the figure after Rochester disassembly is mounted, creating the opportunity to fix the LPG probe mounting kit to the tank.

LPG PROBE MOUNTING KIT AND PIPE

As can be seen in the figure, the Rochester level gauge on the tank was disassembled and the metal adapter manufactured for the 35 mm tank inlet described above was mounted here with a flanged connection. It is made of stainless steel material through the adapter and the lower point is welded with a stainless stopper, and the mounting kit pipe we need for the LPG probe is passed through and mounted on the tank. The probe buoy moves on this pipe. The pipe length can be adjusted according to the tank diameter. After the appropriate measurement, the record of the LPG Installation kit is tightened and sealing is ensured and pressure losses are prevented. The magnetostrictive probe will be mounted on the tank by passing through the pipe.

MAGNETOSTRICTIVE PROBE

The picture shows the metal adapter manufactured for the 35 mm tank inlet, the LPG mounting Kit and the level probe mounted on the tank through the LPG mounting Kit. Now all the equipment to be used on the tank is assembled.

The level probe has the same sensitivity as the probes we use in fuel tanks. Since there is no water measurement in LPG tanks, there is no water measurement feature. It has sensors that detect temperature at 6 points. The probe is connected directly to the Veeder Root control panel, transmitting the liquid level height and the average temperature detected by the sensors to the console.

Probe OIML 85: ‘Automatic Level Gauges for measuring the level of liquid in stationary tanks’ certification and also has 3rd party certification showing VR compatibility with the IP (Ingress Protection) classification system, which we attach great importance to and will be very important in the application in LPG tanks. Bad weather, rain, etc. Considering the conditions, the importance of the resistance of the probe to be mounted above ground against these conditions is obvious.

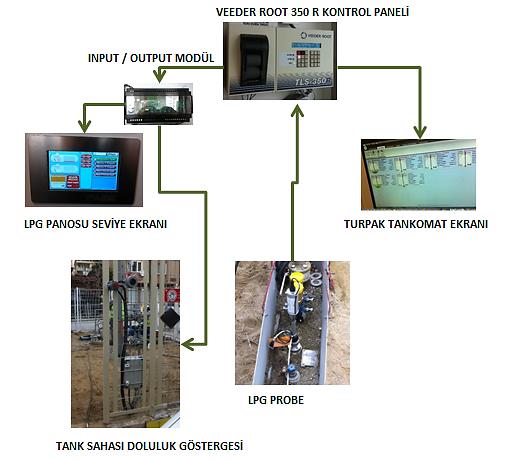

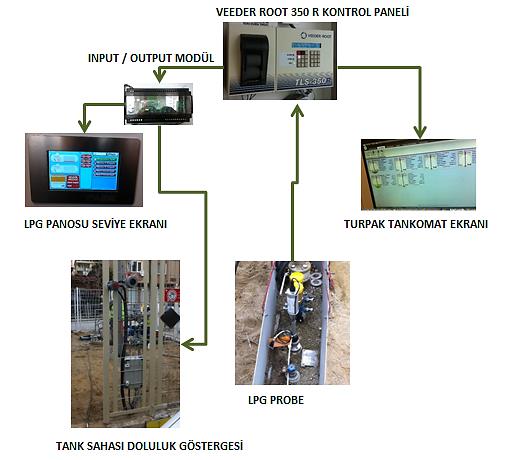

4-20 mA / 0-5 V Input – Output Module for LPG panel

As it is known, LPG panels receive tank level information from the Rochester on the tank and operate some safety and warning systems in the LPG system with this information. After the Rochester disassembled and LPG probe assembly to be made from this point, this equipment was manufactured in order to transmit level information to the LPG panel. This module communicates with the VR control panel and receives the level information of the LPG tank and sends the appropriate output signal to the LPG panel according to this information. At the same time, an external display showing the filling rate of the tank in % is placed in the tank area and is connected to this module.

TANK FIELD, DIGITAL TANK OCCUPANCY DISPLAY

As a requirement of both filling, operative and standards, a digital display was also placed in the tank field in order to show the filling rate of the tank in the tank area after Rochester disassembly. It has also been possible to see it from the outside without entering the tank area. The device is directly connected to the Input – Output Module, which also sends a level signal to the LPG panel. It has an ex-proof structure suitable for the tank field.

SYSTEM CONNECTION & FLOW DIALOGUE