01.02.2019 Istanbul

The Importance of Maintenance in Automatic Brush Car Wash System

The automatic brush car wash system is a must for stations today. Car washes with pressurized and automatic brushes are widely used at the stations. In terms of ensuring customer satisfaction, automatic brush car washes are becoming increasingly common in the sector. In addition, in terms of minimizing the risks that may occur during washing, automatic brush car wash systems have much more advanced technological features than their competitors.

The automatic brush car wash system

is extremely reliable, user-friendly and affordable in terms of price. After the installation of the system, it is necessary to periodically check the system in accordance with the standards, in other words, to maintain it. Treatments can be classified as daily, weekly, monthly and semi-annually. It is important that the maintenance that needs to be done on a daily and weekly basis is provided by an authorized personnel at the station, and that the monthly and semi-annual maintenance is provided by an accredited company. The purpose of daily and weekly maintenance is to ensure the continuity of the system and to take quick action by detecting any risk that may occur early. The purpose of monthly and semi-annual maintenance is to extend the life of the system and to ensure the continuity of customer satisfaction.

Personal protective equipment (hard hat, goggles, work shoes, gloves, etc.) before starting the maintenance process. It must be worn. During any work in the washing area, the energy of the system must be disabled by pressing the emergency stop button in order to prevent work accidents that may occur. Maintenance programs should be divided into 4 as daily, weekly, monthly and semi-annual and should be done in a planned manner and should be acted upon as planned.

Procedures to be done in daily controls;

• Compressor air pressure and oil control,

• Discharge of compressor water,

• Cleaning of the washing area and around the movement rail,

• Splash guard panel safety switch control,

• Top, vertical and rim wash brush controls,

• Chemical controls,

Procedures to be done in weekly controls;

• Dryer safety switch bar control,

• Light barrier sensor controls,

• Tear and damage control of the upper brush carrier belts,

• To ensure that there are no leaks in mechanical installation connections,

• Suspension control of brushes,

• Cleaning of bottom wash water sprayers,

• Cleaning the sprayer on the machine,

• Control of water consumption,

• Control of the float in the water tank,

• Control of the Ph value of the water (Ph range should be between 6.5-8)

• Recycling system control

During brush checks, the brushes should be checked manually and it should be ensured that there are no substances that may damage the vehicles in the brush. While filling the chemicals in the washing machine, they should be filled in such a way that they do not come into contact with any part of the body, and filling operations should be carried out using a canister with a suitable mouth in order to prevent the chemical from spilling on the floor.

Surface and area cleaning of washing machines is also of great importance in terms of machine continuity and customer satisfaction. With a suitable chemical and brush, the outer frame of the washing machine should be cleaned and thoroughly rinsed at certain time intervals. As a result of these processes, the service life of the washing machines will increase and provide better service to users.

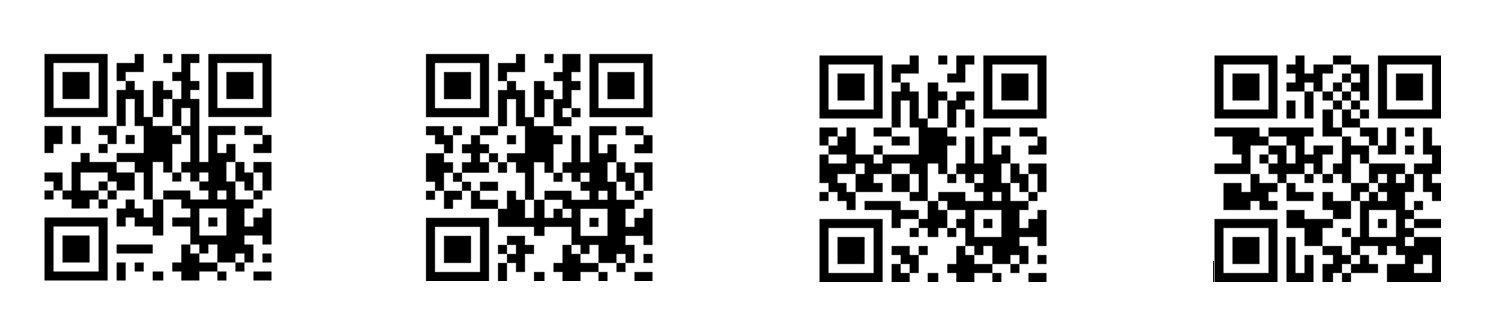

Daily Maintenance Weekly Maintenance Monthly Maintenance Semi-Annual Maintenance

You can watch our maintenance videos in order using the QR codes found above.